Diverter Valve: Enhancing Efficiency in Bulk and

Solid Material Handling

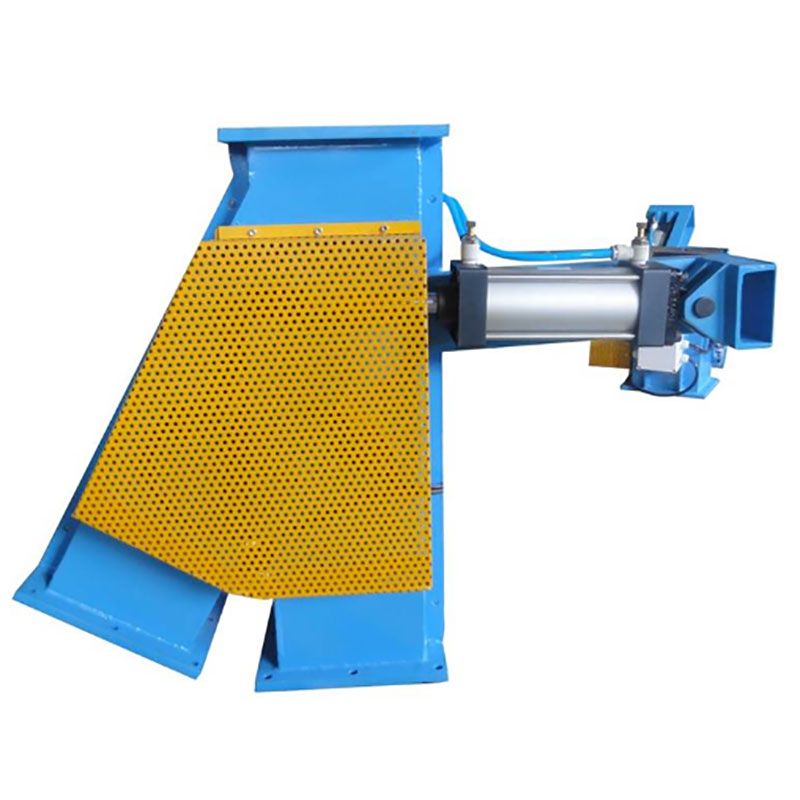

In the realm of bulk and solid material handling, the Diverter Valve, also commonly known as the 3-way direction change valve or bypass valve, has emerged as a game-changer in optimizing material flow and ensuring seamless operation. This versatile device is designed specifically for solid materials such as powders, particles, powder-particle mixtures, and even flakes, playing a pivotal role in switching the flow direction of materials within conveying systems.

Revolutionizing Material Handling

The Diverter Valve boasts a fully sealed structure, making it an ideal choice for outdoor applications where environmental factors can significantly impact performance. Its ability to seamlessly redirect material flow within piping systems to designated equipment ensures uninterrupted processing and enhances overall system efficiency.

Key Features and Advantages

Durability and Strength: Crafted with precision casting, the shell and main components of the Diverter Valve are constructed to be sturdy and highly resistant to deformation. This ensures long-lasting performance even under demanding conditions.

Smooth Flow Path: The valve’s smooth and polished interior ensures that material flows effortlessly, minimizing the risk of clogging and maximizing throughput.

Versatile Design: Available in various configurations, including rotating plate and barrel types, the Diverter Valve can be tailored to suit specific material properties and transportation requirements. Users can also select the appropriate installation angle based on their conveying route needs.

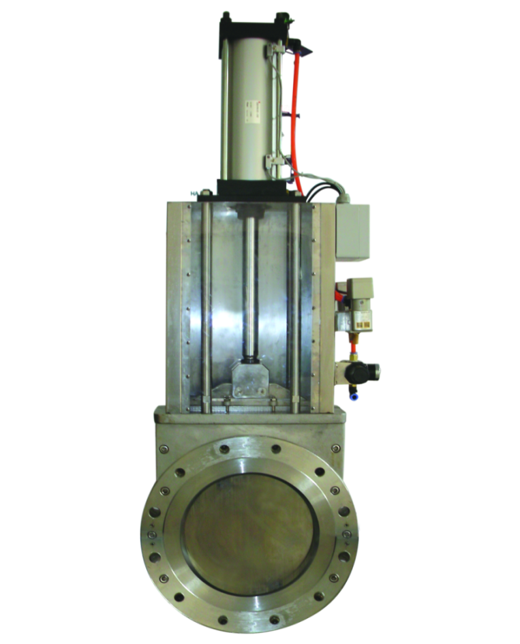

Pressure and Seal Capabilities: For applications requiring pressure sealing, special seal structures can be integrated to fully satisfy operational demands. This ensures leak-free performance even in high-pressure environments.

Food-Grade and Pharmaceutical-Grade Standards: With a polishing accuracy of up to 400#, the Diverter Valve meets the stringent hygiene standards of the food and pharmaceutical industries, guaranteeing safe material handling.

Material Versatility: Offered in a range of materials, including stainless steel (SS304, SS304L, SS316, SS316L), and carbon steel, the Diverter Valve caters to diverse requirements, ensuring compatibility with various materials.

Automated Control System: Equipped with an advanced control system, the Diverter Valve ensures high operational reliability and efficiency, reducing the need for manual intervention.

Industry Applications

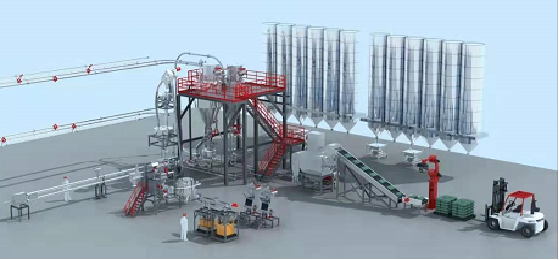

The Diverter Valve finds widespread application across various industries, including chemicals, pharmaceuticals, food processing, mining, and more. In the pharmaceutical sector, its food-grade capabilities ensure safe and hygienic handling of sensitive materials. Similarly, in the food industry, the valve’s ability to handle a wide range of powders and particles, from flours to spices, streamlines production processes.

Conclusion

The Diverter Valve is a testament to the ongoing advancements in powder and particle handling technology. Its innovative design, durability, and versatility make it an indispensable tool for enhancing operational efficiency and ensuring seamless material flow in modern industrial settings. As the demand for precision material handling continues to grow, the Diverter Valve stands poised to play an even more critical role in shaping the future of these industries.