Polypropylene (PP),a widely used thermoplastic, plays a crucial role across a range of industries, including chemicals, pharmaceuticals, and food processing. Its excellent chemical stability, high-temperature resistance, and low density make polypropylene a material that often requires efficient and safe conveying in production processes. To meet the diverse demands of different production processes, choosing the appropriate conveying method is essential. Hanrui Puzer also provides technical solutions for the application of polypropylene, helping you address your conveying needs more effectively.

I. Polypropylene Conveying Principles

Polypropylene conveying involves various technologies and equipment, and the choice of conveying method depends on factors such as material properties, transportation distance, and production environment. Below are several common polypropylene conveying methods and their working principles:

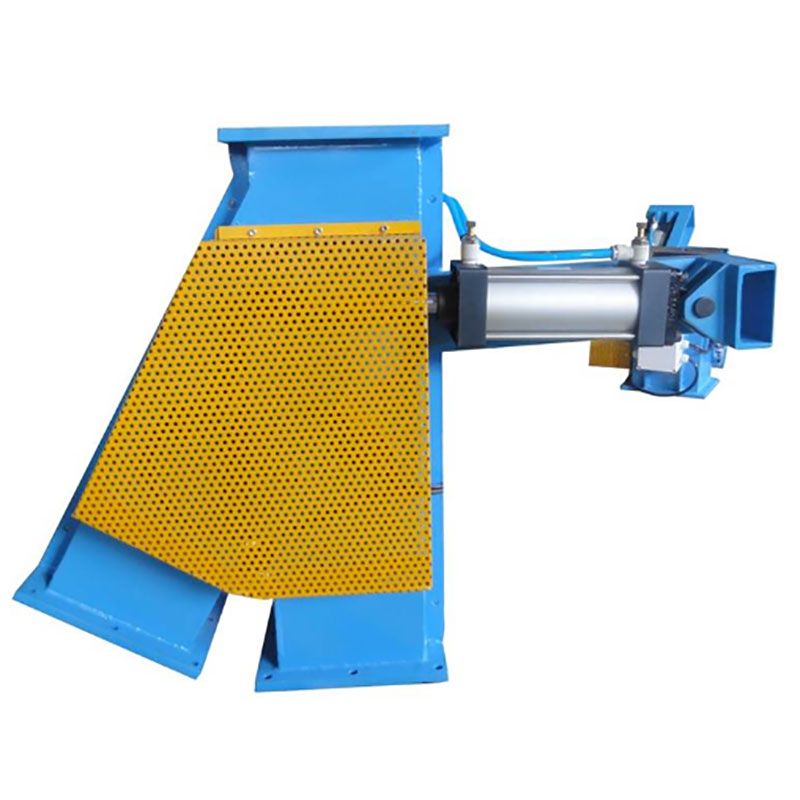

1. Screw Conveyor

A screw conveyor is a commonly used for transporting polypropylene pellets, powders, or mixtures. The working principle is based on rotating spiral blades that push the polypropylene material along the conveying pipeline. Screw Conveyors are ideal for short-distance transport and simple directional changes. They are especially effective in buildings with limited space and multiple pieces of equipment, and can be used for long-distance conveying, particularly when handling polypropylene pellets with good flowability.

- Screw Conveyor

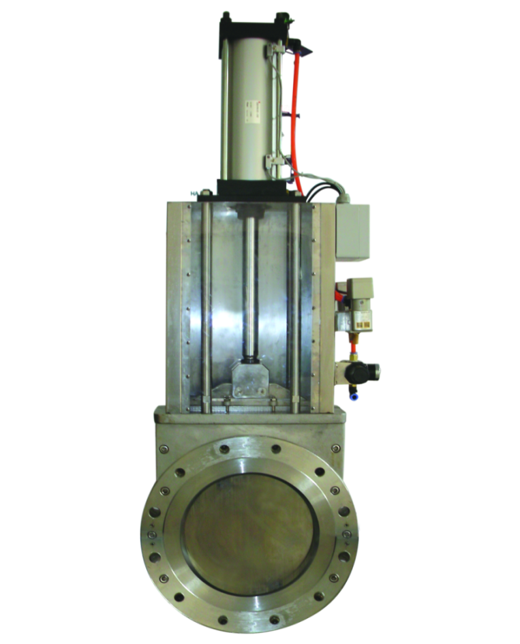

2.Pneumatic Conveying System

A pneumatic conveying system uses compressed air to transport polypropylene pellets or powders to their destination. This method is suitable for long-distance conveying in spaces with limited room and numerous other machines. Pneumatic systems are particularly effective for conveying materials at higher temperatures (≥150°C). Additionally, when operated in a closed environment, they prevent material spillage while enhancing the cleanliness of the production area. Pneumatic conveying systems offer precise control of airflow and material flow, preventing material blockages and damage.

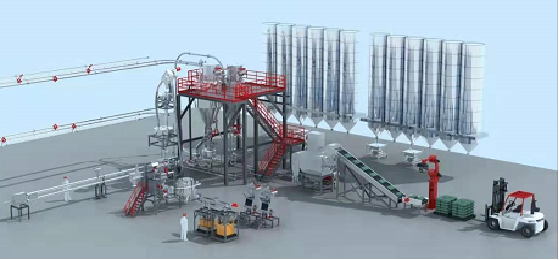

II、Hanrui Puzer’s Services

Efficient conveying of polypropylene is an essential part of modern production processes. Choosing the right conveying system can not only improve production efficiency but also reduce energy consumption and operational costs. With years of technological expertise and extensive project experience, Hanrui Puzer provides comprehensive polypropylene conveying solutions, covering everything from design and installation to maintenance.We ensure that each customer’s production system operates efficiently and reliably.

If you have any inquiries or need sassistance with polypropylene conveying systems, feel free to contact Hanrui Puzer. We offer professional services and technical support to help optimize your production processes, making them more efficient, environmentally friendly, and safe.If you require any information, please click on ‘ Get a Quote’ or email us at caroline@hanruipuzer.com, and we will get back to you as soon as possible.