Tube Chain Conveyor Known as Tubular Disc Conveyor

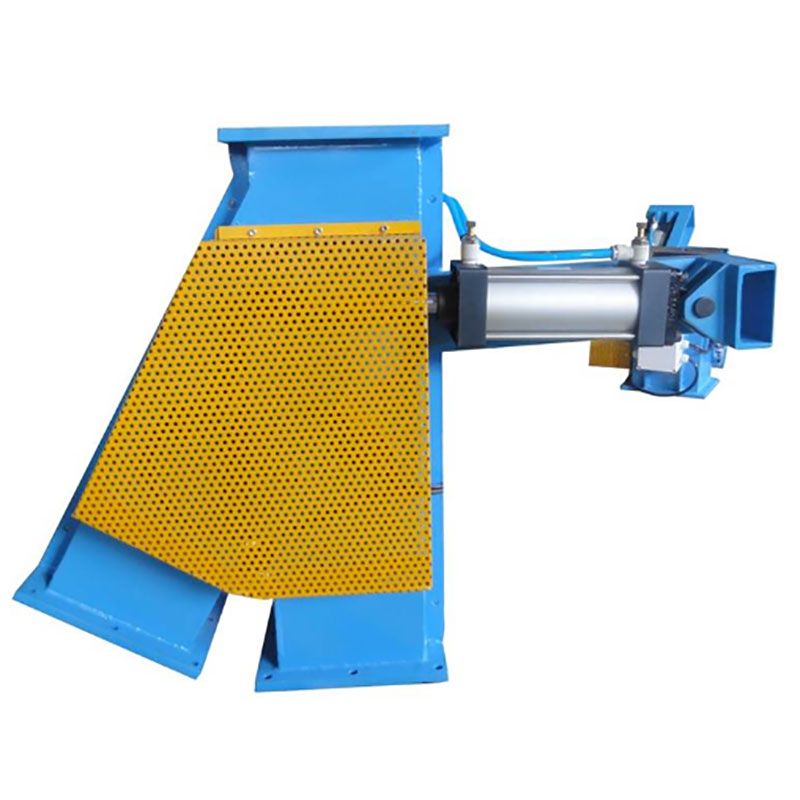

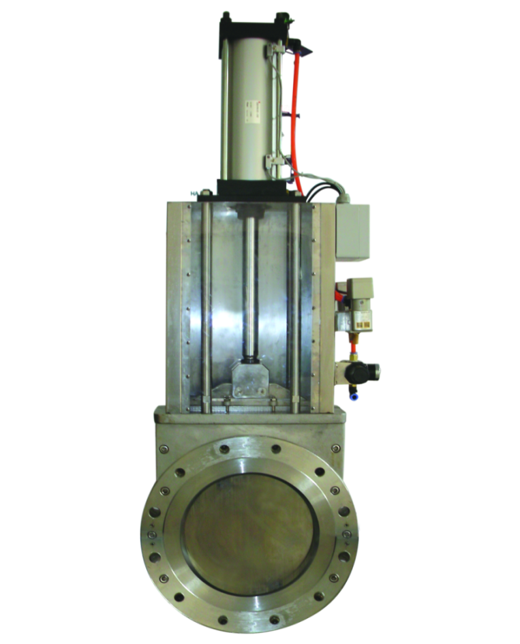

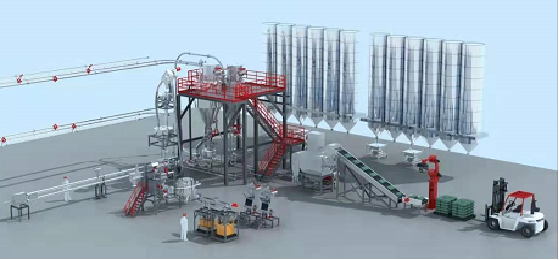

Tube chain conveyor known as tubular disc Conveyor ,as a bulk material conveying device, it widely used in industrial production line and logistics delivery system. It consists of chain and tubes, it transports the material from one point to another destination by chain’s moving.

Tube Chain Conveyor because of its smooth moving ,less wearing and tearing, it suitable for conveying all sorts of granular, powdery, friable bulk materials.

Tube Chain conveyor mainly classification:

- By diameter

It has 3 inch diameter,4 inch diameter,5 inch diameter,6 inch diameter,8 inch diameter - By internal composition

It has Cable with disc type conveyor, Chain with disc type conveyor, Plate with Chain type conveyor.

- By transporting direction:

It has horizontal type tube chain conveyor, vertical type tube chain conveyor, horizontal with vertical combained tube chain conveyor.

Tube Chain Conveyor Features:

- Fully enclosed conveying system, dust free.

- 2.Conveying material from micron sized fine particles to granules up to 10 mm.

- 3.Robust and versatile, widely application.

- 4.Can be discharged in multi-destination.

- 5.Smooth moving, reduce wear and tear.

Tube Chain Conveyor Widely Application:

- Rubber and plastic industry: powder like PP,PVC,PE, granule like ABS, PC, PP, PE, etc.

- Construction material: Cement, clay, yellow sand, quartz sand, clay, silicon powder, calcium carbonate powder, white dolomite powder, wood chips, glass wire, silicon dioxide, etc.

- Fine Chemical: Dyestuffs, Pigments, Coatings, Carbon Black, Titanium Pigment, Iron Oxide, Pottery Powder, Heavy Calcium Carbonate, Fine Calcium Carbonate, Soap Clay, Activated Carbon,etc.

- Pesticides: Urea, ammonium chloride, ammonium bicarbonate, bicarbonate of soda, solid insecticide, etc.

- Food industry: Flour, starch, cereals, milk powder, food additives, fish oil, etc.

- Metal and other powders: Tungsten powder, copper ore powder, coal powder, lump phosphate, bauxite, etc.

Difference between tube chain conveyor and pneumatic conveying

| Tube Chain Conveyor | Pneumatic Conveying |

| Suitable for short distance conveying | Long distance conveying |

| Mechanical conveying, need power supply | Pneumatic conveying, needs air consumption |

| Lower temperature | High temperature conveying is available |

| Smooth moving, ensure integrity of the product, nearly no breakage | Has breakage |

| Small tearing and wearing | N/A |

| Low energy consumption | N/A |

Hanrui Puzer Bulk Handling Technology (Shanghai) Co.,ltd,as a leading high-tech enterprise specializing in powder and particle solid material handling engineering,it supplies high quality tube chain conveyor with reliable price .We can offer different tube chain conveyor to meet customer’s demands.