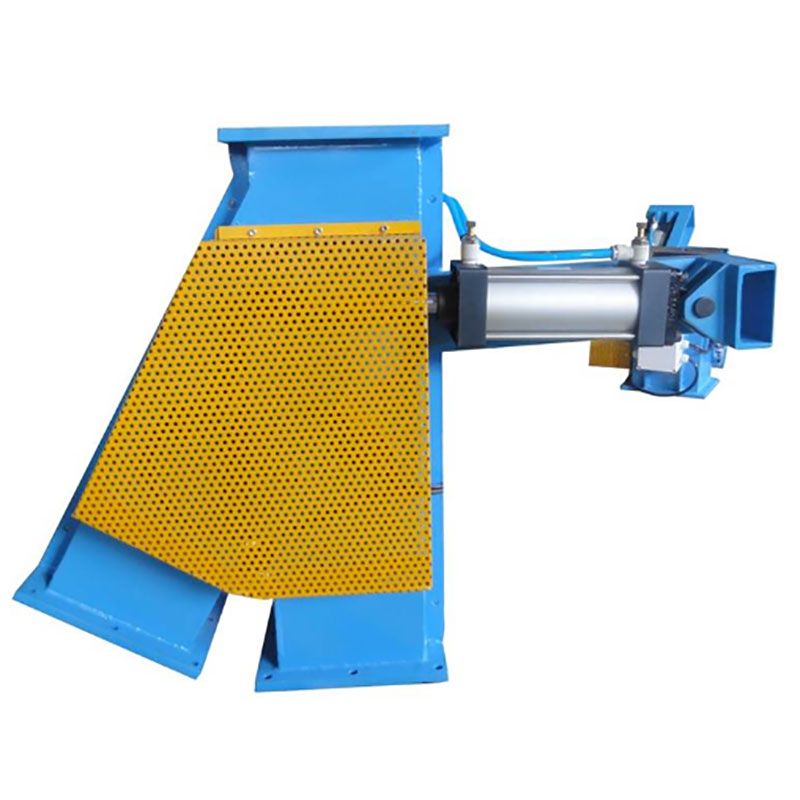

The 3-way diverter valve (flap type) from Hanrui Puzer is an ideal choice for industrial material handling systems due to its lightweight, compact, low-pressure-drop, multi-material, and maintenance-friendly features. Hanruipuzer is committed to providing high-performance and reliable products to help you improve production efficiency and reduce operating costs. If you are looking for an efficient and reliable diverter valve, Hanruipuzer’s 3-way diverter valve is your perfect partner!

Lightweight Design with Uncompromised Strength

Hanrui Puzer’s innovative lightweight design revolutionizes diverter valve technology by utilizing advanced computer-optimized structural engineering. Our valves incorporate aerospace-grade aluminum alloys and high-strength composite materials, achieving a remarkable 40% weight reduction compared to conventional steel valves while maintaining superior structural integrity. This breakthrough design yields multiple operational benefits:

-

Material savings of up to 35% through precision casting and machining processes

-

Installation efficiency improvements with 50% less lifting equipment required

-

Structural load reduction on support frameworks by approximately 30%

-

Transportation cost savings due to reduced weight and compact packaging

The secret to this lightweight durability lies in our proprietary HPS (High-Performance Sandwich) construction, which combines:

-

A rigid outer shell with reinforced stress points

-

A honeycomb core structure for optimal strength-to-weight ratio

-

Wear-resistant interior lining for extended service life

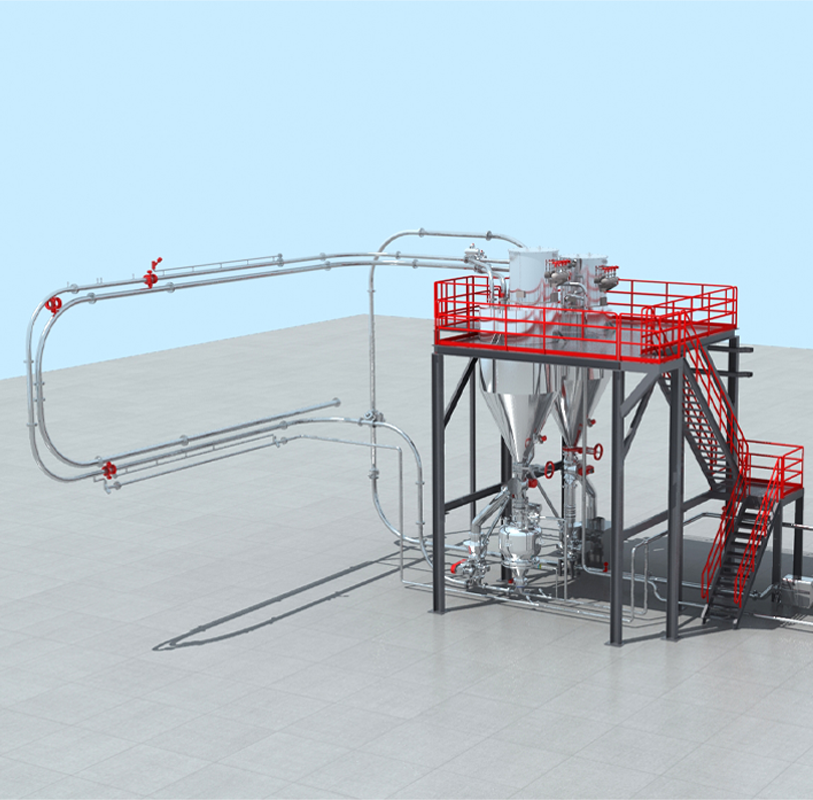

Space-Optimized Compact Structure

Our 3-way diverter valve represents the pinnacle of space-efficient design, featuring:

-

Minimal footprint with dimensions up to 45% smaller than industry standards

-

Modular configuration allowing flexible installation in any orientation

-

Integrated mounting system that adapts to existing pipework with minimal modification

The compact design incorporates several innovative features:

-

Radial flow channels that minimize turbulence and pressure loss

-

Oversized access panels for easy maintenance in confined spaces

-

Stackable installation capability for multi-line applications

Comprehensive Material Selection for Demanding Applications

Hanrui Puzer offers the industry’s most extensive material portfolio, with each option engineered for specific operational challenges:

-

Stainless Steel Series (316L/904L)

-

Corrosion resistance to pH 1-14

-

Electropolished interior (Ra ≤ 0.4μm) for ultra-clean applications

-

Sanitary clamp connections available

-

-

Wear-Resistant Solutions

-

Tungsten carbide-lined ports (HRC 70+)

-

Ceramic-impregnated surfaces for extreme abrasion resistance

-

Removable wear plates with 5mm replaceable thickness

-

-

Specialty Alloys

-

Hastelloy C-276 for severe chemical environments

-

Titanium options for chloride-rich media

-

Duplex steels for high-temperature/pressure applications

-

Each material option undergoes rigorous testing, including:

-

1000-hour salt spray testing

-

ASTM G65 abrasion resistance verification

-

FDA/USP Class VI compliance certification

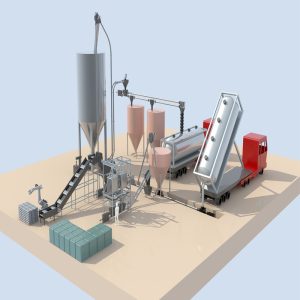

Universal Application Capabilities

The Hanrui Puzer 3-way diverter valve delivers exceptional performance across diverse industries:

Chemical Processing

-

Handles concentrated acids/alkalis at temperatures up to 450°F

-

Zero-leakage design prevents cross-contamination

-

ATEX-compliant versions available

Food & Beverage

-

EHEDG-certified hygienic design

-

Clean-in-Place (CIP) compatibility with 3A sanitary standards

-

Quick-disassembly for USDA inspections

Pharmaceutical Manufacturing

-

Validatable to FDA 21 CFR Part 11

-

USP Class VI compliant elastomers

-

Isolatable for containment applications

Cement & Minerals

-

Tungsten carbide wear protection for 100,000+ cycle durability

-

Dust-tight operation with <0.01% leakage

-

High-temperature versions to 750°F

Energy & Utilities

-

Fly ash handling capacity to 100 TPH

-

Explosion-proof configurations

-

Remote monitoring capability

Advanced Flap Design for Optimal Flow Dynamics

Our patented Low-Angle Diverter Technology (LADT) features:

-

15° deflection angle (vs. conventional 45° designs)

-

Aerodynamic flap profile reducing pressure drop by 60%

-

Balanced pivot mechanism requiring 75% less actuation force

Performance benefits include:

-

Near-instantaneous switching (≤0.5 seconds)

-

Energy savings up to 30% from reduced system backpressure

-

Extended seal life due to minimized turbulence impact

The valve’s SmartFlow monitoring system (optional) provides:

-

Real-time flow rate measurement

-

Position confirmation feedback

-

Predictive maintenance alerts

Custom Engineering Solutions

Hanruipuzer offers complete application engineering support:

-

Computational Fluid Dynamics (CFD) analysis

-

Material compatibility studies

-

Factory acceptance testing

-

Turnkey installation packages

This comprehensive approach ensures optimal valve selection and performance for every unique application, delivering measurable improvements in:

-

System uptime (99.9% availability)

-

Maintenance cost reduction (up to 40%)

-

Energy efficiency (20-35% savings)

-

Product quality consistency

With global certifications including ASME, PED, and CE marking, Hanruipuzer diverter valves meet the most stringent international standards for safety and performance.

Contact us today to learn more about our products and explore customized solutions! Hanrui Puzer Bulk Handling Technology (Shanghai) CO., Ltd

Tel: +86 021-51917600

Mail: Caroline@hanruipuzer.com