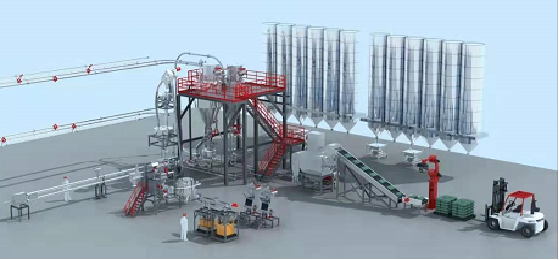

Pneumatic conveying systems

Pneumatic conveying systems serve as the backbone of various industries, facilitating the efficient transportation of materials in powdered or granular form. Hanrui Puzer Bulk Handling Technology (Shanghai) Co., Ltd., a prominent player in this domain, offers valuable insights into a range of pneumatic conveying systems, each meticulously crafted to address specific industrial requirements.

- Dilute Phase Pneumatic Conveying: This method involves materials gracefully suspended within the airstream, ideal for non-abrasive and non-degradable materials, ensuring gentle handling.

- Dense Phase Pneumatic Conveying: Operating at slower velocities, dense phase conveying allows materials to form a dense plug, minimizing the risk of degradation and damage, particularly suitable for fragile materials.

- Vacuum Conveying: Harnessing negative pressure, vacuum conveying adeptly moves materials through pipelines, particularly advantageous for delicate materials, commonly used in pharmaceutical and food processing industries.

- Pressure Conveying: This method utilizes positive pressure to propel materials through pipelines, making it suitable for longer distances and higher capacities in various industrial settings.

- Lean Phase Pneumatic Conveying: With a higher ratio of air to material, lean phase conveying results in a lean mixture, effectively conveying materials over longer distances with minimal wear.

- Two-Phase Pneumatic Conveying: Also known as dense-dilute conveying, this method seamlessly integrates elements of both dilute and dense phase conveying, offering flexibility to cater to a wide range of materials and conveying requirements.

Conclusion: Understanding the diverse types of pneumatic conveying systems is crucial for selecting the most suitable method based on material characteristics and industry-specific needs. Whether ensuring the gentle transport of fragile materials or efficiently conveying bulk solids, the versatility of pneumatic.