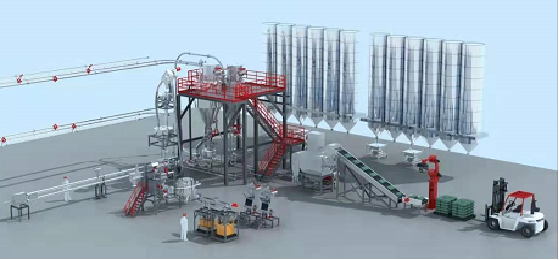

On September 29th, Hanrui Puzer won the bidding of Lihua Group’s 50,000 tons/year ASA special resin plant mixing and additives system project. After nearly 5 months’ continuous efforts of the project team, the project is about to enter the stage of shipment and transportation, installation guidance, and system debugging!

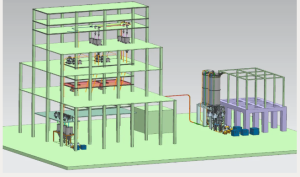

Mixing system: including mixing material storage bin and system accessories. Additive pneumatic piping system: a total of 9 pneumatic piping. Large-capacity mixing system: 2 sets of 1000L high mixing system. Additive Feeding System: 6 sets of loss-in-weight feeding system Automatic Feeding System: including 2 sets of automatic feeding system, which is composed of feeding system, screw feeding system and weighing system. It also includes pipes, valves, electrical instruments, PLC control system and so on.

With a total investment of 2.2 billion RMB, this project is not only a key project in Shandong Province, but also will become an important driving force for the conversion of old and new power in the field of polymer materials in China.

As the winning bidder of this project, Hanruipuze has long been deeply engaged in the field of agriculture and new materials, and has accumulated a wealth of experience in project engineering and technology skill transfer. The company always adheres to the development concept of innovation-driven and quality-driven, and has established long-term and stable partnership with the first batch of entrepreneurial petrochemical and new material enterprises, and jointly completed a number of projects with industry influence. Participating in the first ASA resin project in China is both a challenge and an opportunity for Hanruipuze. The company attaches great importance to every stage of the project, from the preliminary technical planning, detailed engineering design to the later production and manufacturing, each stage is subject to strict risk management and implementation of the gatekeeper.

Upcoming Products

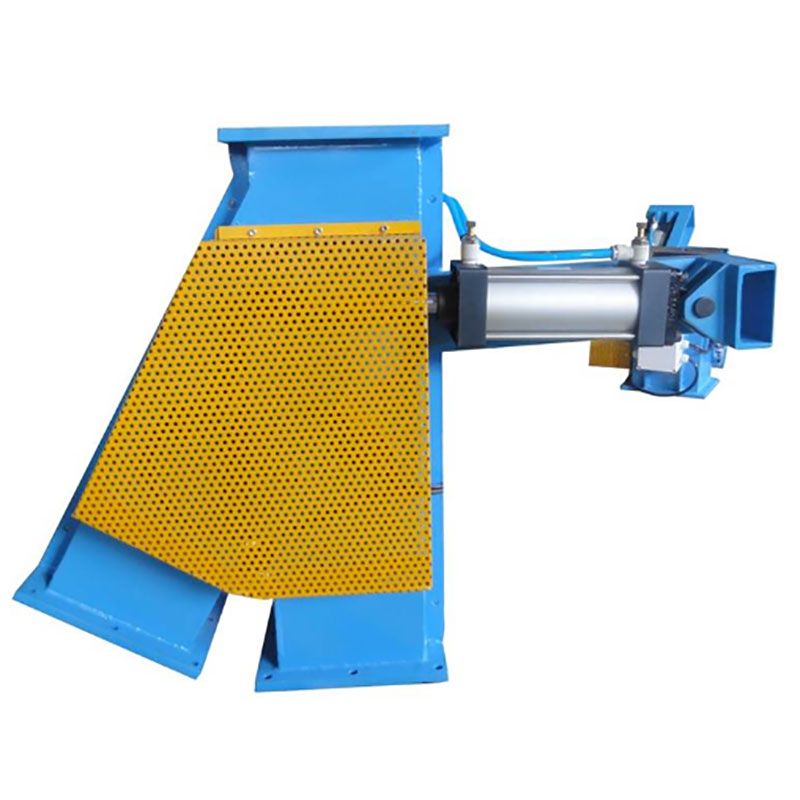

MIXER

Cyclone Separator

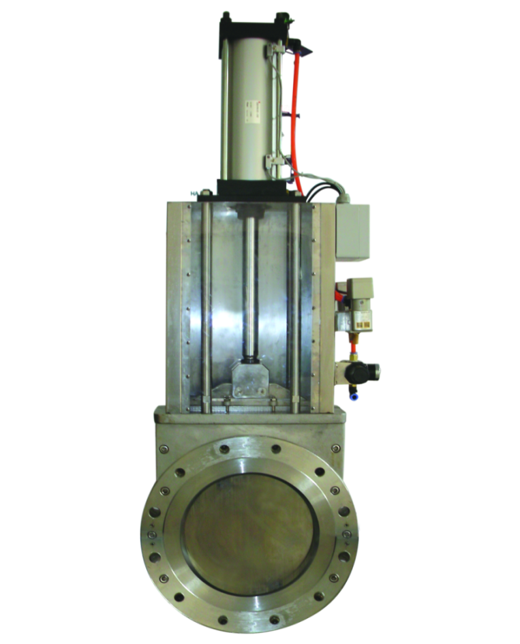

Rotary Feeder Bag Filters

HanruiPuzer has 31000 square meters of production base, invested in the construction of the first domestic “intelligent factory powder engineering technology center service platform”, including multimedia digital display center, solid bulk powder testing center, engineering technology innovation center, customer service center, etc., and has a pneumatic assembly line system, pipe chain line, automatic unpacking, loading, AGV intelligent transportation and other experimental lines, is willing to work together with global partners to build, cooperation and win-win cooperation. With pneumatic assembly line system, pipe chain assembly line, automatic unpacking, loading, AGV intelligent transportation and other experimental lines, we are willing to work together with more global partners to build a win-win cooperation.