Pneumatic Dilute Phase Conveying

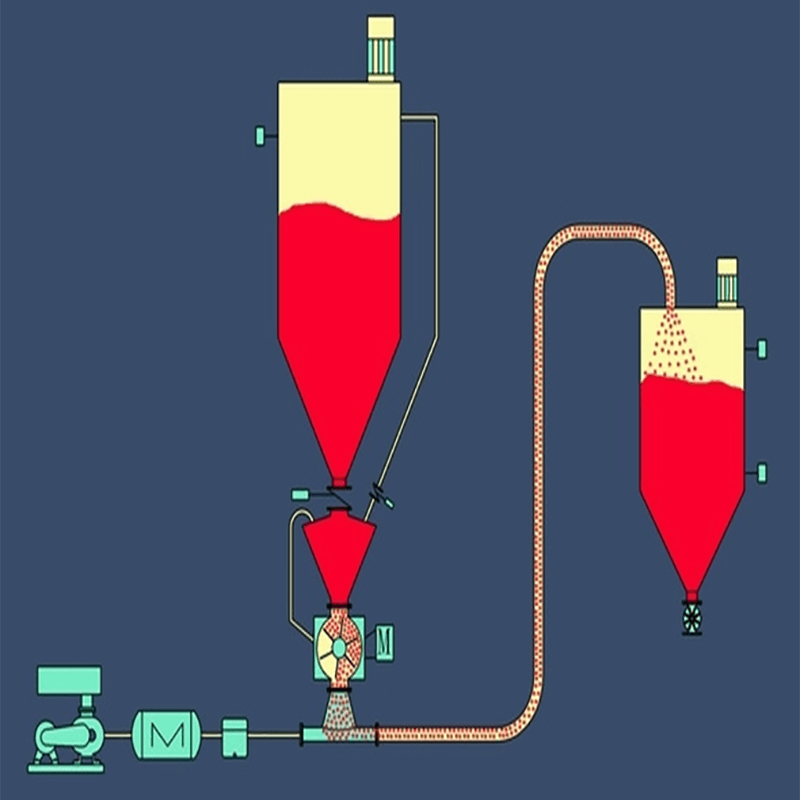

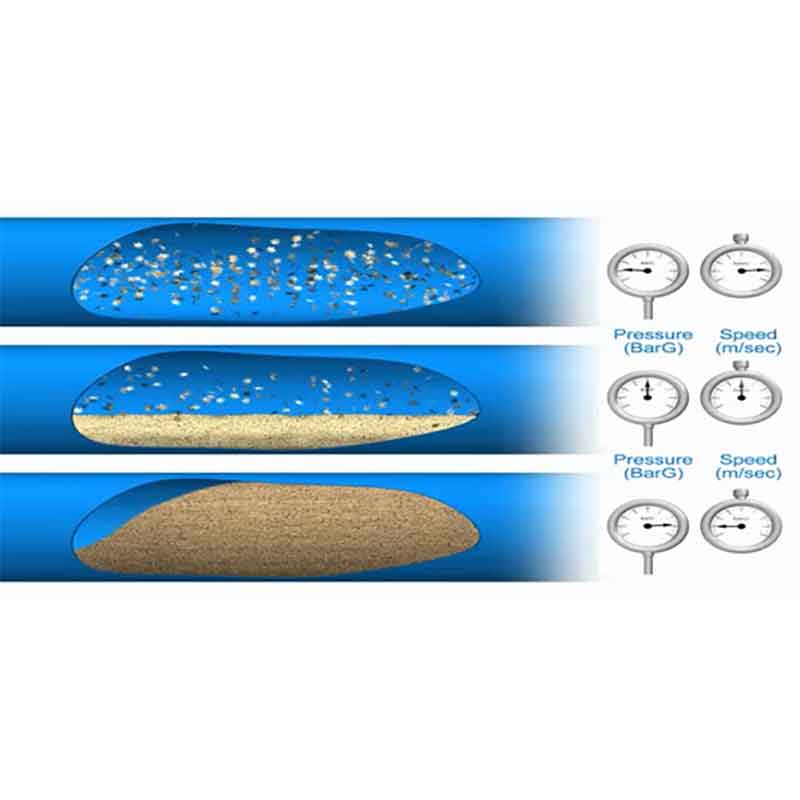

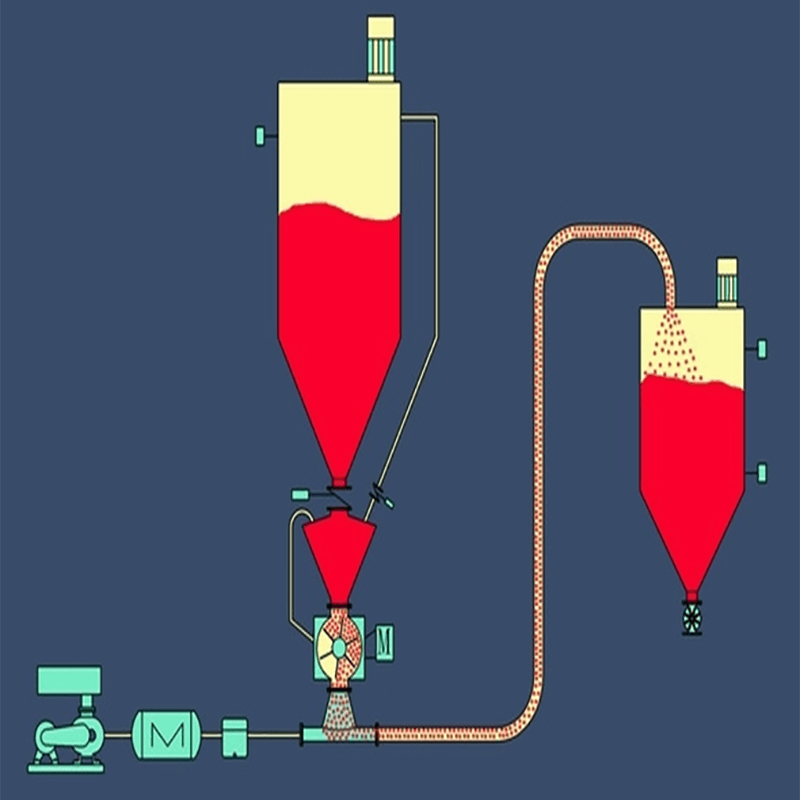

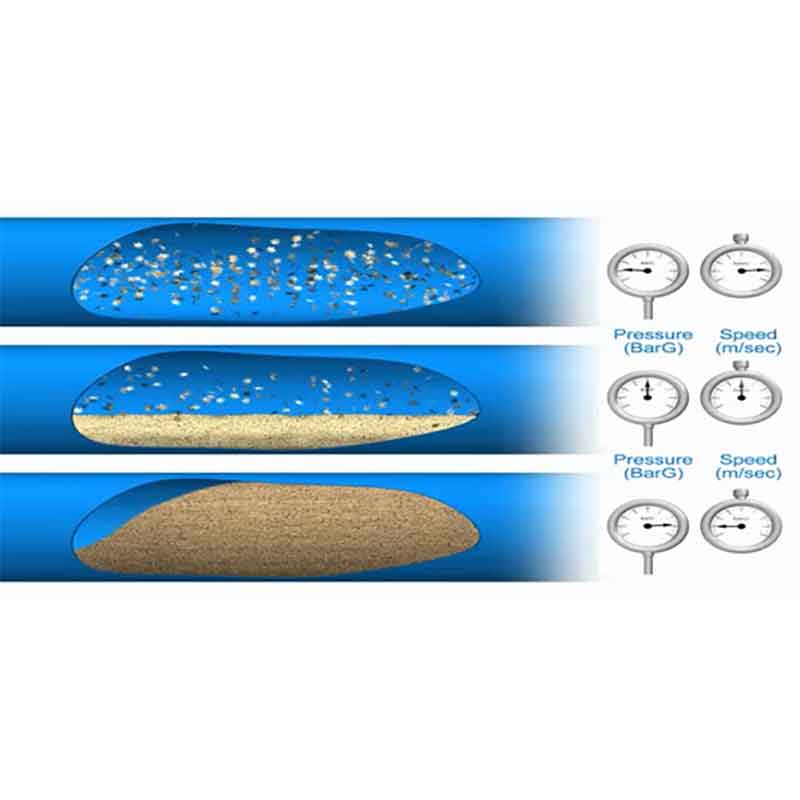

Pneumatic Dilute phase conveying is a continuous process,that use constant low pressure (generally no more than 0.1Mpa) air as driving forece to move the bulk material with a high speed ,the conveyed material mostly are light bulk density,and it takes on suspended state in the pipelines according the material properties. The dilute phase pneumatic conveying system consist of pipelines,blower,rotary valve,receiver hopper,bulk storage silo, etc . silo ,it consist of pipelines,blower,rotary valve,receiver hopper,bulk storage silo, etc .

Hanrui Puzer supplying high qulity pneumatic dilute phase conveying system ,it widely used in bulk material handling, like lime, cement, flour, resins, fly ash, soda ash, and other dry bulk chemicals.

1. High conveying speed.

2. Continous Conveying from a single point to multiple destination.

3. Lower working pressure no more than 0.1Mpa.

4. Easy to installation and maintance.

5. Widely application.

Pneumatic Dilute Phase Conveying Specification Sheet

| Working medium | Powder or granular material |

| Pipe material | SS304/316,Carbon steel, wearing pipe with lining ceramics,etc |

| Flange standard | ASME / HG/T20592-2009/ HG/T20615~20635-2009/etc |

| Explosion-proof | Optional |

Get a Free Quote of Pneumatic Dilute Phase Conveying

Pneumatic Dilute Phase Conveying Application

- Power and Energy Industry,like fly ash,Lithium carbonate powder,rock,etc

- Mining industry.

- Constrution industry :Cement

- Chemical Processing,Resins,soda ash

- Plastics Manufacturing,such as PE,PP,PVC,Polymer,etc

- Food&Pharamutical industry like flaor,cornflour,cereals,etc.

Related News

Pneumatic conveying systems Pneumatic conveying systems serve as the backbone of various industries, facilitating the efficient transportation of materials in […]