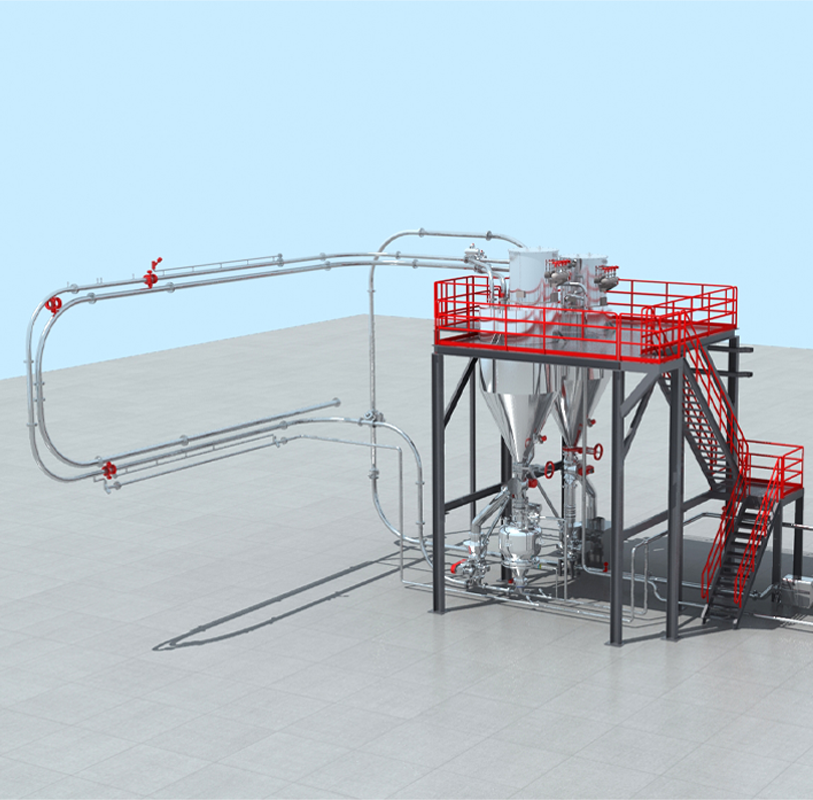

In the world of powder and bulk material handling, efficiency, reliability, and innovation are critical. Hanrui Puzer’s cutting-edge Tube Chain Conveyor Systems stand out as a game-changing solution for industries ranging from chemicals and food to pharmaceuticals and new energy. With a focus on closed-loop transportation, energy savings, and intelligent control, Hanrui Puzer delivers unmatched performance tailored to modern industrial needs.

The Core innovation from Hanrui Puzer

The core innovation of Hanrui Puzer’s Tube Chain Conveyor Systems lies in their unique closed-loop transportation mechanism. Unlike conventional pneumatic or mechanical conveyors that often struggle with material degradation, cross-contamination, and environmental contamination, our systems guarantee zero dust leakage throughout the entire conveying process. This breakthrough design not only ensures compliance with increasingly stringent global environmental and workplace safety regulations but also preserves material integrity, particularly crucial for high-value products in pharmaceutical and food-grade applications. Independent field tests have demonstrated energy savings exceeding 30% compared to traditional pneumatic systems, translating to substantial reductions in operational expenditures – a benefit that compounds significantly over the system’s extended service life.

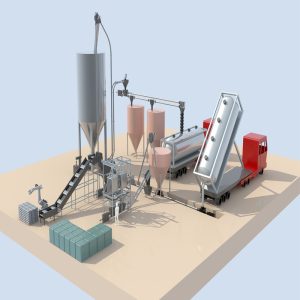

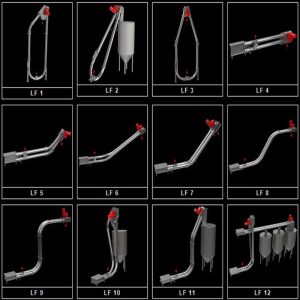

The flexibility and uniqueness of the design scheme

What truly distinguishes Hanrui Puzer’s solution is its exceptional flexibility in system configuration. Our Tube Chain Conveyors can be engineered to accommodate virtually any plant layout, featuring seamless transitions between horizontal, vertical, and multi-angle curved routing with radii as tight as 1.5 times the tube diameter. This spatial adaptability is complemented by an impressive material compatibility range – from ultra-fine powders below 10 microns to larger granules up to 20mm, including challenging materials prone to segregation or degradation. The system’s gentle conveying action, with material speeds typically below 0.5m/s, ensures minimal particle breakdown even for fragile crystalline structures.

At the heart of our fourth-generation Tube Chain Conveyors lies an advanced automation ecosystem. The standard PLC-based control system provides comprehensive operational oversight, while optional Iot connectivity enables real-time performance monitoring through our proprietary Hanrui Smart Conveyance Platform. This digital integration facilitates predictive maintenance scheduling, remote troubleshooting, and seamless data exchange with broader factory management systems (MES/ERP). Particularly noteworthy is our AI-driven analytics module, which continuously optimises conveyor performance by analysing vibration patterns, power consumption, and throughput efficiency, delivering measurable improvements in energy efficiency and component lifespan.

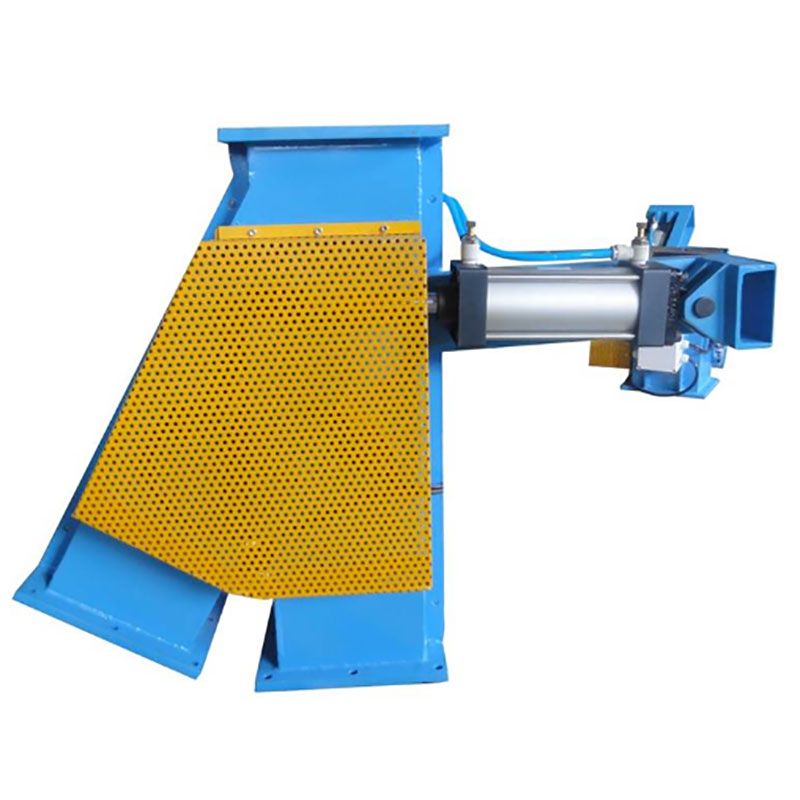

The mechanical superiority of Hanrui Puzer’s systems stems from meticulous engineering details. Critical wear components utilise specially formulated alloy steels with surface hardness exceeding 60 HRC, while food-grade applications feature FDA-compliant polymer chains. Our patented sealing system maintains consistent performance even under negative pressure conditions, and the modular design philosophy ensures swift component replacement with minimal downtime. These features collectively contribute to industry-leading mean time between failures (MTBF) exceeding 25,000 operational hours in typical applications.

The globalization of Hanrui Puzer

Hanrui Puzer’s global footprint includes successful installations across five continents, with particularly strong adoption in several key vertical markets. In the chemical sector, our systems handle everything from titanium dioxide pigments to speciality polymer powders with exceptional reliability. Food and pharmaceutical clients benefit from GMP-compliant designs featuring polished surfaces, quick-release mechanisms, and validated cleaning protocols. The burgeoning lithium battery industry relies on our metal-minimised, contamination-free conveyors for critical electrode material handling. Recent innovations include ATEX-certified explosion-proof systems for combustible dust applications and high-temperature variants capable of continuous operation at 250°C.

Behind every Hanrui Puzer Tube Chain Conveyor System stands our comprehensive support infrastructure. Our engineering team offers everything from initial material testing and flow characteristic analysis to full 3D plant layout simulations. Commissioning services include hands-on operator training and performance benchmarking, while our global spare parts network guarantees rapid response to maintenance needs. The company maintains active R&D partnerships with several leading technical universities, ensuring our solutions remain at the forefront of material handling technology.

As industries worldwide accelerate their digital transformation and sustainability initiatives, Hanrui Puzer continues to pioneer advancements in smart conveyance technology. Current development focuses include energy recovery systems, biodegradable component materials, and enhanced machine learning algorithms for self-optimising operation. These innovations position our Tube Chain Conveyor Systems as not just material handling solutions, but as strategic assets driving operational excellence in the Industry 4.0 era.

Experience the Future of Powder Handling with Hanrui Puzer’s Intelligent Tube Chain Conveyor Systems

Contact our global solutions team today for a comprehensive application assessment and customised system proposal. Discover why leading Fortune 500 companies trust Hanrui Puzer for their most demanding material handling challenges.

📞 Contact us today for a tailored solution!