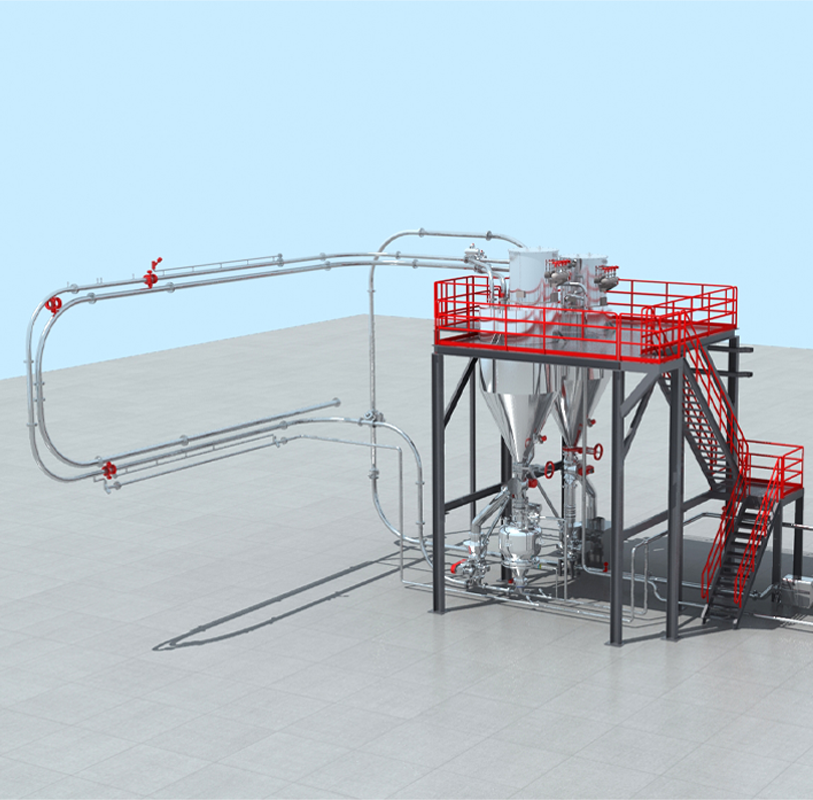

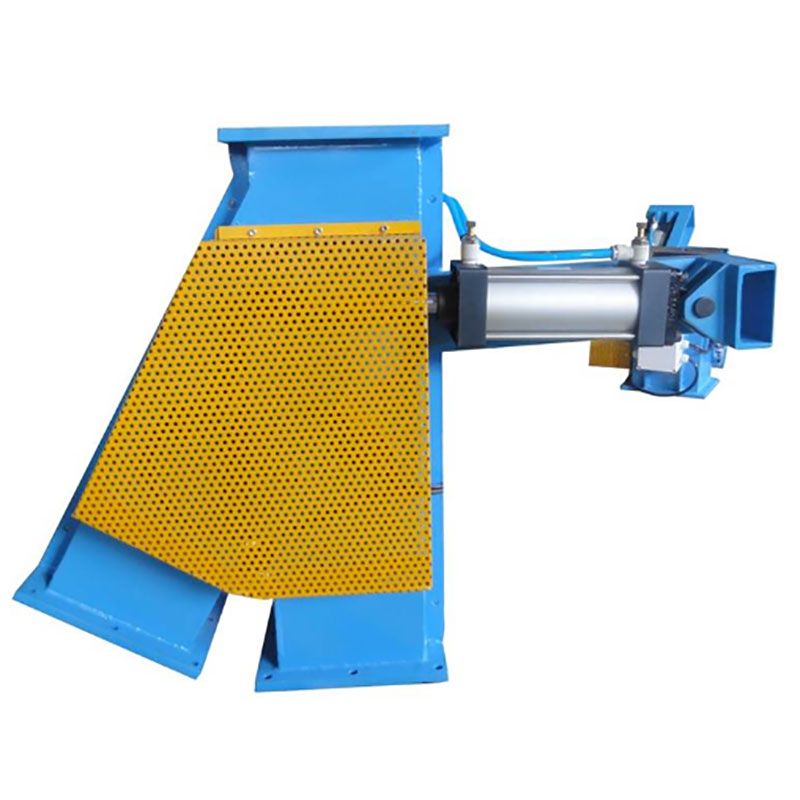

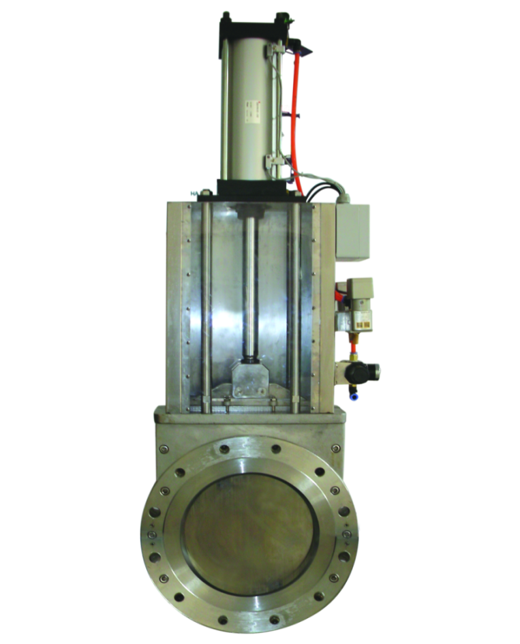

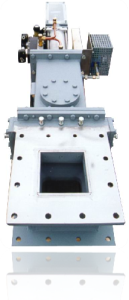

Slide valves, also known as knife valves, insert valves, or knife gate valves, are specialized valves used in conveying systems for solid materials (such as powders, granules, powder-granule mixtures, and flakes). They serve the purpose of opening and closing pipelines, featuring a fully sealed structure that makes them suitable for outdoor environments. These valves are primarily utilized at the bottom of hoppers, silos, or related equipment and can be operated manually, pneumatically, or electrically. Pneumatic slide valves, which may also be referred to as pneumatic insert valves, pneumatic knife valves, or pneumatic knife gate valves, are specifically designed for use in solid material conveying systems to effectively control the flow of materials in pipelines.

1. Features:

- The shell and main components are constructed from precision casting, providing a robust structure with high strength and resistance to deformation, along with an aesthetically pleasing appearance.

- The material transport channel is smooth and clean, ensuring smooth material flow without clogging.

- The knife-edge gate design applies force to the valve seat via an inclined surface when closed, providing excellent airtight performance.

- Polishing precision can reach 400#, making it suitable for conveying food-grade and pharmaceutical-grade materials.

- Various main materials can be selected according to user requirements: stainless steel (SS304, SS304L, SS316, 316L), carbon steel, etc.

- Multiple drive options are available: manual, pneumatic, and electric.

- A complete control system can improve automation levels, ensuring efficient and reliable operation.

2. Application Range:

The slide gate control valve adopts a standardized and modular design with very few worn parts, significantly reducing the user’s need for part replacement and spare parts inventory.

Our Products:

If you have purchasing requirements, we can select the optimal solution for you based on your model.