Using a chain for transmission, the system moves solid materials within a

sealed pipeline.

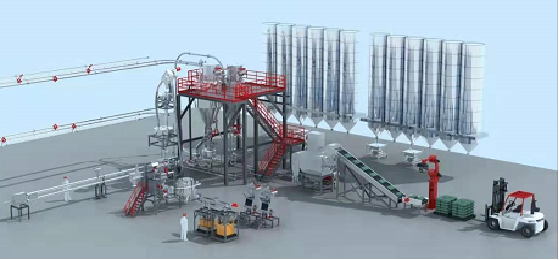

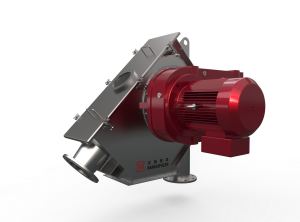

Since Hanruipuzer developed and delivered its first pipe chain conveyor in 2006, the main types of structures have included plate, circular, and rope chains, with circular pipe chain conveyors accounting for over 80% of the installations. It has been applied to PTA, calcium carbonate, urea, ammonia, phosphate fertiliser, PVC, PP, white sugar, caprolactam, clay, lignite powder, sodium aluminate, desiccant, grain husk ash, calcium hydroxide, activated carbon, organosilicon powder, catalyst, raw material medicine and so on.

products features:

1.Completely Sealed Pipeline

2.Low Power Consumption

3.Versatile Material Handling

4.Automatic Feeding for Flowable Materials

5. Smooth Material Transport

6.Multiple Discharge Points

7. Low Operating Noise

8. Easy On-Site Installation

9. Space-Efficient Design

10. Customizable Design

11. Food and Pharmaceutical Compatibility

Product Features

Optimal Conveying Speed:0.1 m/s to 0.45 m/s (for rope chains, 3 to 5 m/s). Conveying Distance:Maximum horizontal single-unit distance of 80 meters (250 meters for rope chains); maximum vertical height of 50 meters (20 meters for rope chains).

Operating Temperature:Maximum temperatures: 60°C for rope chains, 180°C for circular chains, and 680°C for plate chains.

Applicable Media: Uniform solid bulk materials such as powders and pellets, with a maximum particle size of 10 mm.

Project Cases

Pipe chain conveying solutions are suitable for continuous conveying of bulk materials such as powder, small granules and small lumps. It can be combined with horizontal, inclined and vertical conveying. It can also be used for material conveying in explosion-proof areas.

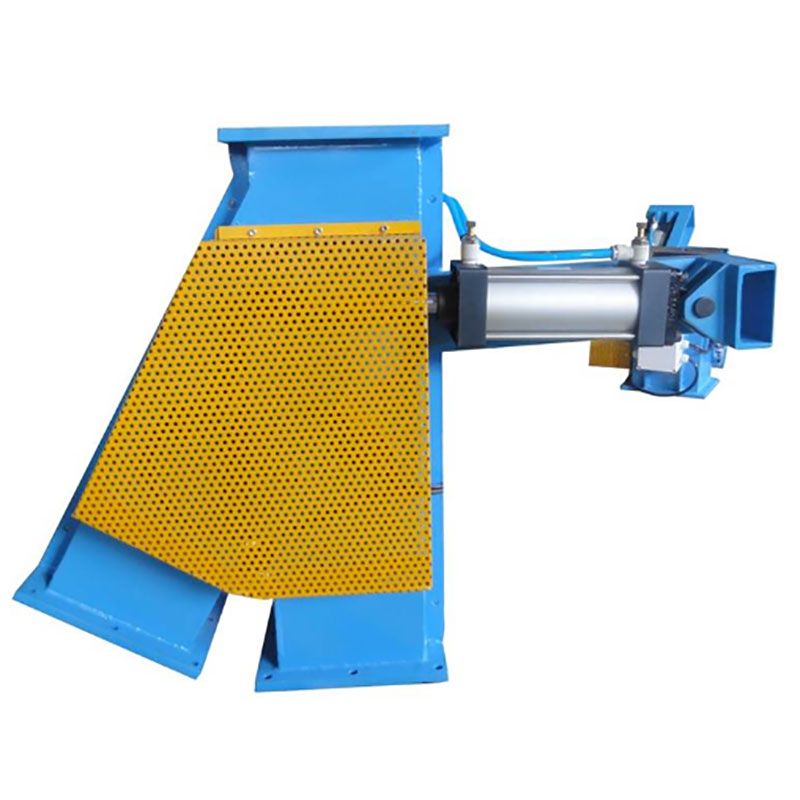

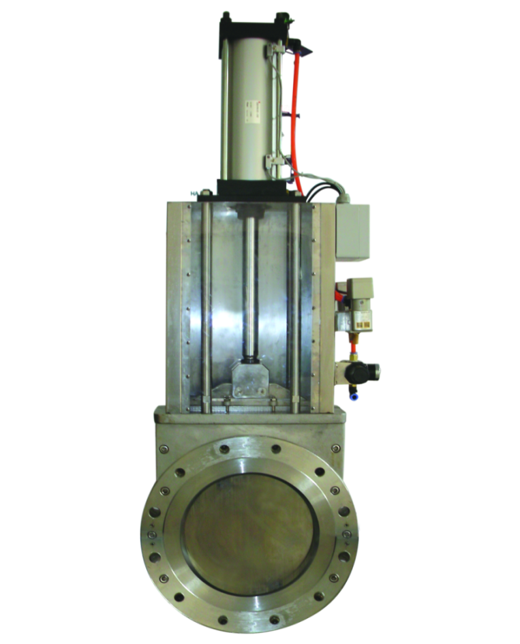

Circular Tube Chain Conveying Automatic tapping structure Automatic vibration structure